- Consists of a rotating and stationary cutter, utilizing a standard impeller.

- Minimal energy consumption (4% or less) for solution

- Designed to break up clogs/ragging

- Hardened cutter material

- Adjustable clearances

- Minimal flow restrictions

- Does not change external pump dimensions

- Retrofittable

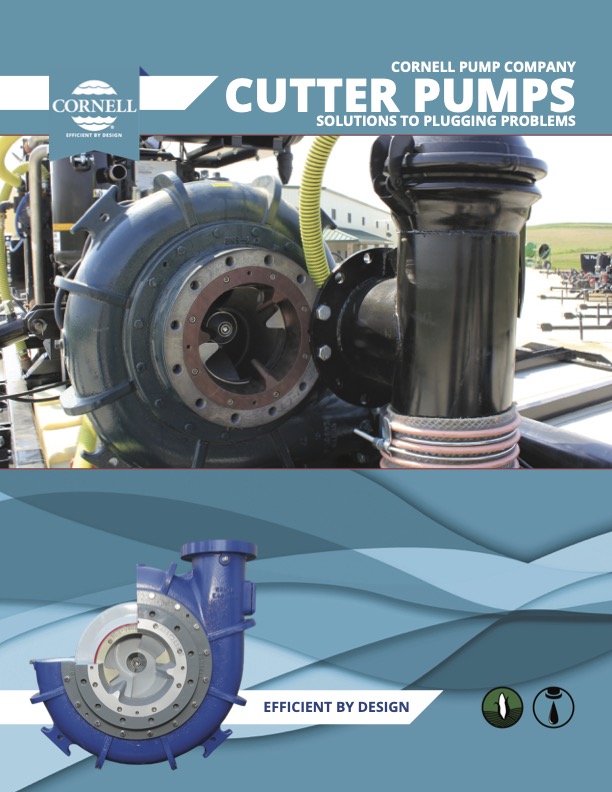

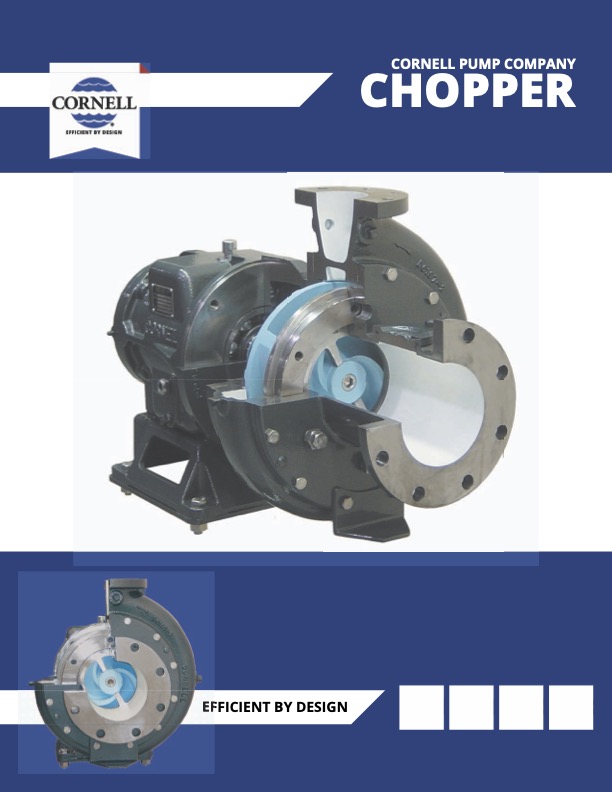

Centex Fluid Products distributes Cornell line of Cutter Pumps. The cutter pump was created in order to address the urgent need of reducing clogging due to ragging and roping. With the increased use of ‘flushable’ materials and extraneous cleaning products, the issue of clogging—leading to downtime, pump destruction, and pipe damage, has increased markedly. Useful in municipal, agricultural, and other markets, the cutters unique stationary and rotating blade design allows material to pass through the impeller that would tend to clog a non-cutter pump. The cutter is adjustable and made from special hardened metal to extended life operation. The cutter impeller can be retrofitted on existing pumps and will not change the external pump dimensions. Cornell’s cutters are offered in two versions: the standard Blade Cutter which can be fitted into virtually any existing pump model or the specially designed Waste Warrior pump models for more aggressive ragging and plugging. Cornell’s Chopper Pump is ideally suited for chopping solids. The standard casing, made of ASTM A536 grade 65-45-12 ductile iron, stands up to robust applications. The Cornell Chopper pump series is a heavy-duty performer.

Features and Benefits

- Special materials of construction

- Cutters are hardened for long life

- Cutters are shaped to minimize flow restrictions

- Designed to break up clogs and prevent ragging

- Saves labor and downtime required to clean out clogs

- Minimal increase to cost of operation

- Breaks up “flushable wipes”, “fatbergs” and other materials in municipal applications

- Breaks up clumps of straw in manure applications

- Cutters in new pumps are covered by our Industry leading, Two-year warranty

- The more aggressive solution, featuring scythe-like edges from the impeller eye, sweeping all the area where the suction pipe meets the volute.

- Handles most aggressive and troublesome clogs and ragging

- Limited energy consumption (around 8%) for solution

- Hardened cutter material

- Insignificant flow restrictions

- Does not change external pump dimensions

- Retrofittable

- Wastewater and sewage pump stations

- Wastewater treatment facilities

- Agricultural waste

- Manure

- Industrial waste

- Sewage by-pass

- Food processing

- Dewatering

- Hydraulic transfer

- Plant wastewater