- Sewage lift stations

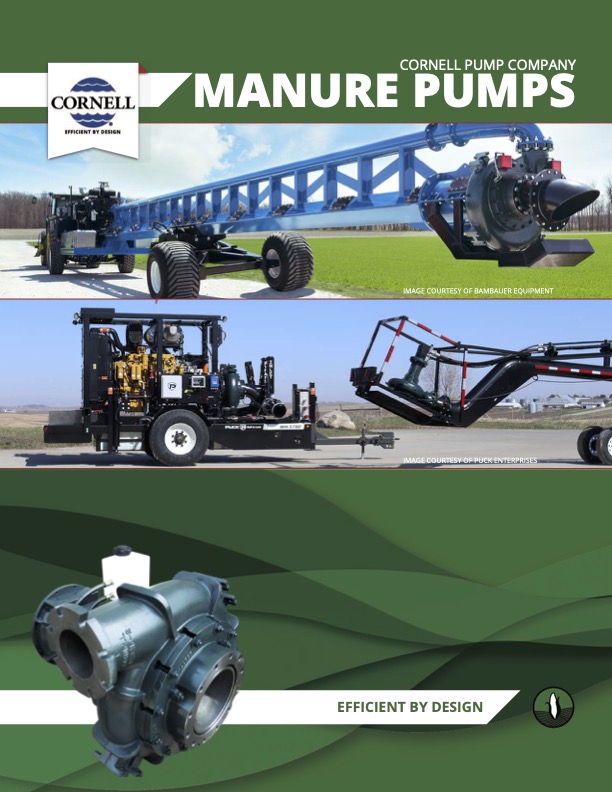

- Manure slurry

- Return activated sludge

- Waste activated sludge

- Water booster

- Sewage bypass

- Dewatering

- Digesters

- Industrial waste

- Light abrasives

- Agricultural waste

- Steel production

- Food processing

- Mining

- General industrial

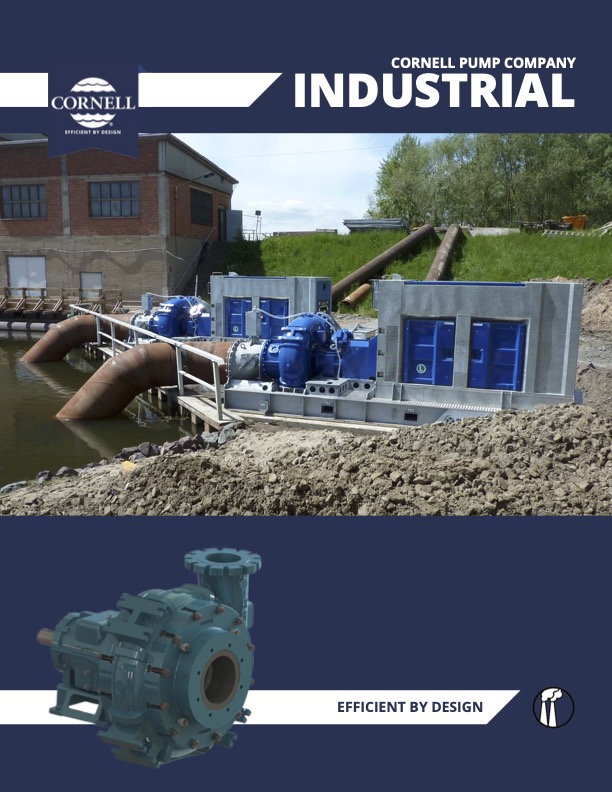

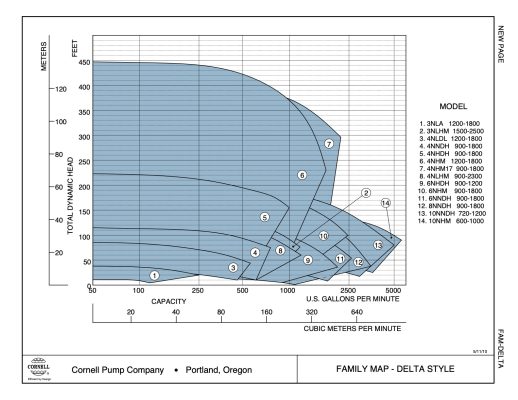

Cornell’s Solids handling pumps are designed to address solids present in the pumping media. Whether it is disposal or hydro-transportation of delicate solids, Cornell has an array of pumps for a vast range of applications in the Municipal, Industrial and Agricultural markets.

They are available in a variety of configurations and construction materials to suit the most demanding solids handling applications. Cornell’s solids handling pumps feature enclosed, semi-open, or Delta impellers. These pumps are available in a variety of mounting configurations including Close-Coupled, SAE Engine, Horizontal, and Vertical Mounted.

Features and Benefits

- Replaceable wear rings

- Double volute

- Bearing life to 100,000 hrs or more

- Dynamically balanced impellers

- Heavy-walled castings

- Replaceable shaft sleeves

- Various mounting configurations

- Compact design

- Low shaft deflection

- High efficiency

- High suction lift

- Two-year warranty

- Oversized bearings

- Patented Cycloseal® design

- Low cost of repair

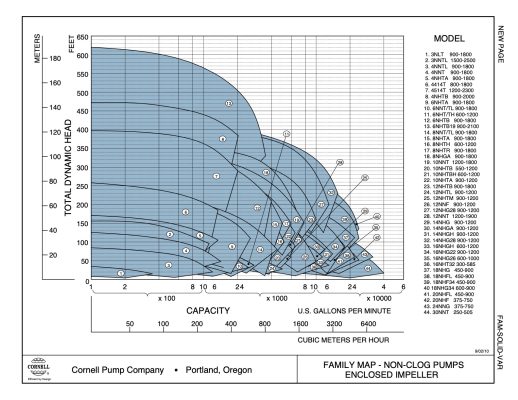

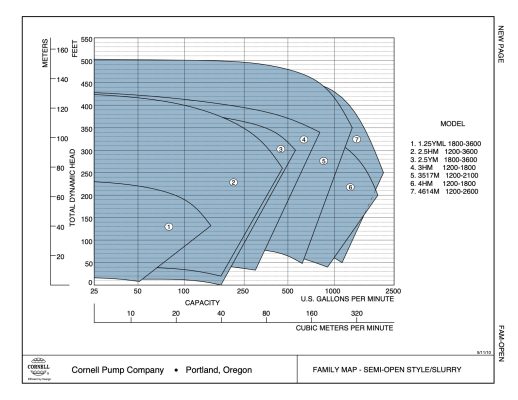

Data Sheets: